The Various Types Of Epoxy

Flooring Systems

Are you one of the people that think that epoxy flooring only offers a gray, boring and industrial-like finish? What if we told you that epoxy flooring offers dozens of variants for different settings with an endless selection of finishes to fit any style? Well, today, our goal is to inform you about all of the amazing variants of epoxy flooring systems on the market, so let’s get started!

100% Solid Epoxy Systems

The 100 percent solid epoxy is one of the strongest and longest-lasting flooring solutions on the market today. Where other epoxy variants use fillers in its mixture, 100 percent epoxy uses pure epoxy, resulting in an ultra-durable finish. With the use of pure epoxy, you can expect to have a high-performing flooring system when properly installed. Even though it’s a high-grade flooring system, some disadvantages are bound to come with the advantages. Down below, you will find the pros and cons of 100 percent solid epoxies:

Pros

- Offers high damage tolerance

- Can be ready for use in as little as 1 hour

- Can last high traffic areas 20-25 years

Cons

- Is best installed by trained professionals

- Hard to obtain without a contracting license

- Will be more expensive to obtain that lesser epoxies

Water-Based Epoxies

A step down from the 100 percent solid epoxy flooring system is the waterbased epoxy system. This is because unlike the solid epoxies, water-based epoxies use water to fill in some material. While the coating may be less durable than solid epoxies, the materials tend to go much farther as the material becomes easier to spread. But, water based epoxies can still be used in light-duty commercial facilities, commercial garages and in residential homes or garages. One of the biggest disadvantages though of using a water-based epoxy is the added cure time due to the required dissipation of the water-based elements. The average cure time for a water based epoxy is between 48-72 hours in optimal temperatures of 80- 90 degrees with most materials.

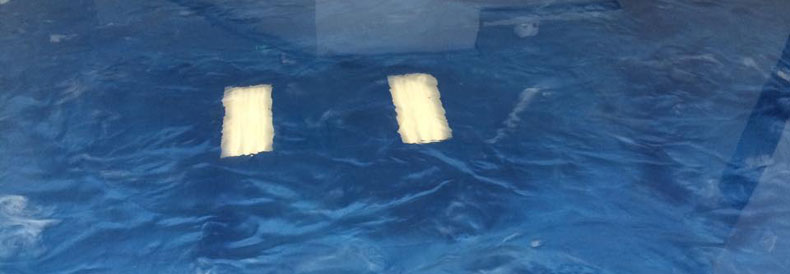

Metallic Epoxies

Metallic epoxies are one of the newest forms of epoxy flooring and are most commonly used in the residential and commercial market. Due to the fact that most metallic epoxies use the 100 percent solid epoxy, you will find that pricing reaches upwards of 10-15 dollars a square foot, but they are more than worth it! With the use of specialized metallic pigments, contractors use brushes, solvents, and squeegees to produce jaw-dropping finishes that are one of a kind every time. With this technique, your flooring can replicate the appearance of clouds, burning embers, and even crashing waves. Metallic epoxy isn’t everyone’s cup of tea and down below you can find the pros and cons of using metallic epoxy flooring:

Pros

- Can make an area up to 150% brighter with lighter colors

- Can be installed using the 100 percent solid epoxy base

- Provide an easy to clean surface with a seamless finish

Cons

- Only trained contractors can install it perfectly

- Near impossible to DIY with toxic fumes

- Will cost 4-8 dollars a square foot more than standard epoxy

Epoxy Base Finishes

Do you feel like epoxy flooring really isn’t what your home needs or is clashing with the style you are trying to achieve? Well, that doesn’t mean that you can’t use epoxy to protect your concrete as there are epoxies that can be used as base coats. For example, vapor lock epoxies are most commonly used in basement waterproofing and other areas like kitchens or laundry rooms that are exposed to moisture, protecting your concrete from water damage. Another example of an epoxy base coat is the anti-static epoxies that are non-conductive, making it the perfect system for data centers, server rooms or anywhere that handles or works on sensitive electronics.

Well, there you have it, the most common forms and variations of the revolutionary epoxy flooring system. Now that you know that not all epoxies are a dull, gray and depressing flooring system, maybe it is time to think about which epoxy is right for you. Remember, while using a contractor can cost you more upfront, they will save you thousands of dollars in the long run with warranties and other benefits like free quotes. No matter if you don’t use epoxy, DIY the epoxy or use a contractor, we wish you the best of luck on all of your future renovations.